Differentiating to other vertical probes

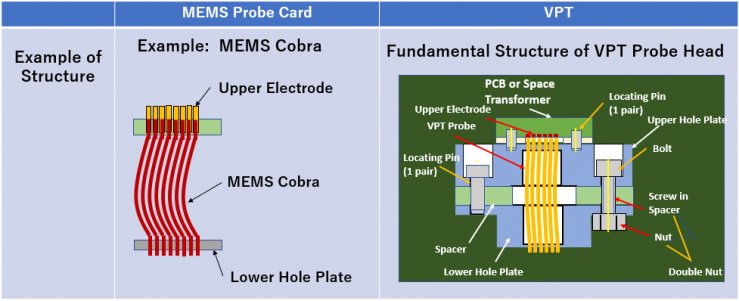

【1】 Comparison with MEMS probe (1)

Comparison with MEMS probe (2)

Comparison with MEMS probe (3)

| MEMS Probe | VPT | ||

| Availability of Iridium as probe material |

Iridium is not available to MEMS for the following reasons: (1) Iridium has high melting temperature (2,466℃), and it is hard to apply vapor deposition or ion sputtering. (2) Iridium which reaches to the necessary place in deposition target is to limited very little. So, yield rate of precious Iridium is extremely low. |

・ Iridium has actual achievement of long probe life, 4,000k T/D in canti-lever probe. ( In plant of Japanese device manufacturer.) ・Iridium is precious material, but the material cost is lower than Rhodium. By making it very thin wire, material cost per pin becomes low. Cost of Drawing thin wire is not low, but we have a good company to cut wires to pins in very good cost. |

|

| Availability to Fine Pitch and Limit |

At present MEMS probe card companies which can realize Fine Pitch of 40μ are only two, Formfactor and Techno probe. But even for them, full array 40μ pitch is not easy. |

For VPT, there is a prospect of full array Fine Pitch of next generation, 36μ ( by applying 20μ diameter Iridium pin, hole diameter 25μ, and wall thickness between holes 11μ.) |

|

| Cleaning frequency and probe life | ① Affinity of probe material and pad materials |

MEMS probe materials contain Gold, Silver, Copper, or Palladium. These materials have high affinity with electrode pad materials such as Copper and lead-free solder. |

Iridium is rare metal as Rhodium and does not make any compound and has no oxide on surface. Iridium has low affinity with electrode pad materials. |

| ② Cleaning Frequency and Running Cost | Debris of pad material oxide stich to MEMS probe and part of it make compound with probe, resulting in increase of cleaning frequency and higher running cost. | Debris of pad do not make compound with probe made of Iridium. Debris just stich to probe mechanically, and they are easily removed by non-abrasive cleaning gel. → Probe life is prolonged. | |

|

③ Probe Life |

Hardness of probe is low. Due to frequent cleaning, probe life is short. |

Iridium has high hardness and ware resistance. As cleaning frequency is low long probe life is expected. | |

| Result of lead-free solder rubbing test | Lead-free solder contains Silver, which has high affinity with MEMS probe. |

Probe made of H3C was heavily wet by lead-free solder. |

Rare Metal probe made of Rhodium was not wet by solder after alcohol washing. |

| On-Site Repair Pin by Pin |

・MEMS Cobra : impossible. ・Other MEMS such as Pin Inserted Type : Unknown |

There is a plan which has high feasibility to achieve on-site repair pin by pin. | |

| Prospect of Growth |

With the appearance of VPT, MEMS will be out of date in the following evaluations 1) High Running Cost 2) Short Probe Life 3) Cost of manufacturing facility is high 4) Productivity is low 5) Availability in Fine Pitch of next generation, 36μ pitch is difficult |

Owing to following differentiation predominant points, VPT will surpass MEMS sooner or later. If VPT took some part of MEMS, its growth will be astronomical value. 1) Production facility cost is one-digit smaller than that of MEMS. 2) Owing to automated pins inserting, outstanding high productivity for high volume pins. 3) It is clearly prospected how to realize fine pitch of next generation of 36μ. 4) Probe cost is low despite its high performance. 5) Low cleaning frequency and low running cost. 6) Long probe life. (Against MEMS probe, more than five times longer probe life is guessed from actual achievement in canti-lever probe and low affinity to electrode pad materials.) |

|

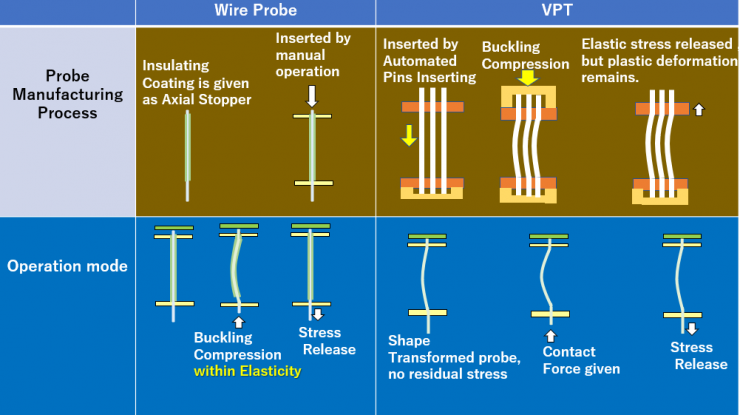

【2】 Comparison with Wire probe (1)

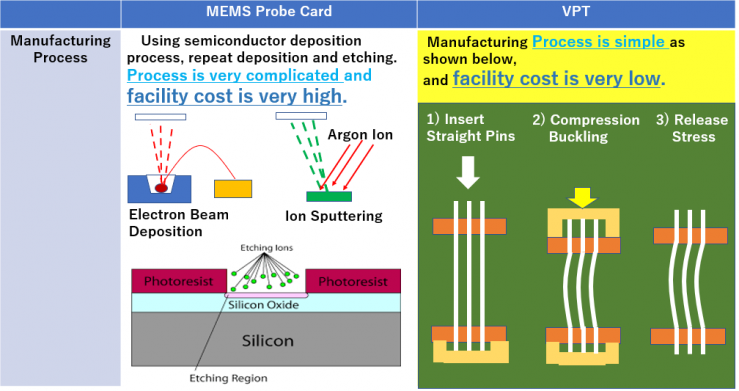

Fundamental Structure of Wire Probe

| Wire Probe | VPT | ||

| Availability of probe material Iridium |

As buckling compression stress in wire probe becomes too large due to high elasticity of Iridium, in many cases Iridium was not available to wire probe. |

Straight pins are transformed to curved form by buckling compression. The curved form is symmetrical cobra shape and stress is bending stress which is controllable. Iridium is available. |

|

| Availability to Fine Pitch |

Insulating coating which acts as axial stopper hampers Fine Pitch. Coated pins are inserted by operator, which causes human error and cost up. |

As VPT probe has the shape like symmetrical cobra, no need for insulating coating as axial stopper. VPT is advantageous in Fine Pitch as straight pins are inserted to jig by automated pins inserting. |

|

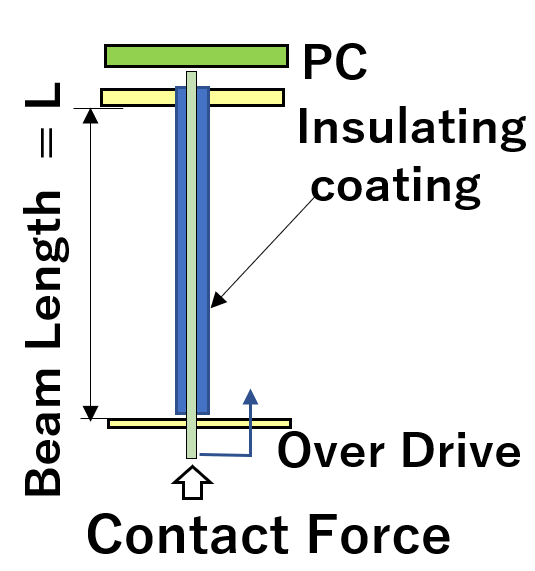

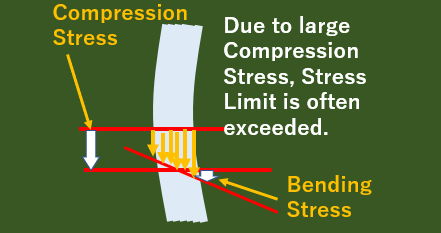

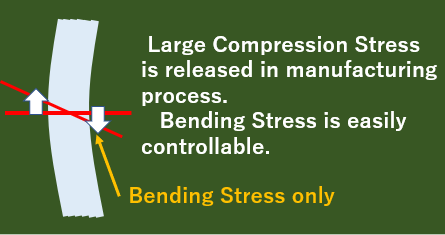

| Stress in Operation |  |

|

|

【3】 Comparison with Wire probe (2)

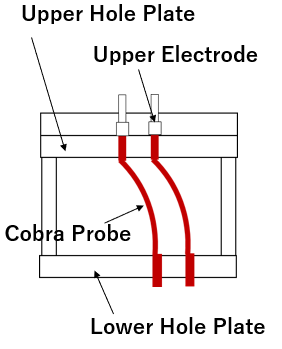

【4】 Comparison with Cobra

Fundamental Structure of Cobra Probe

| Cobra Probe | VPT | ||

| Availability of Iridium | Iridium is not available to cobra as shocking power is given in press formation of cobra, which causes micro crack inside Iridium pin. | Available | |

| Availability of Fine Pitch |

It is difficult to insert hole plate jig in case of fine pitch as shape of cobra is complicated. Human operator is required to insert cobra into jig, which causes human error and cost up. |

VPT is very advantageous in Fine Pitch as straight pins are inserted to hole plate jig by automated pins inserting. | |

| Prospect to Growth | Fine Pitch is difficult, and growth is not expected. | Great growth is expected as VPT has differentiating challenges to MEMS. | |